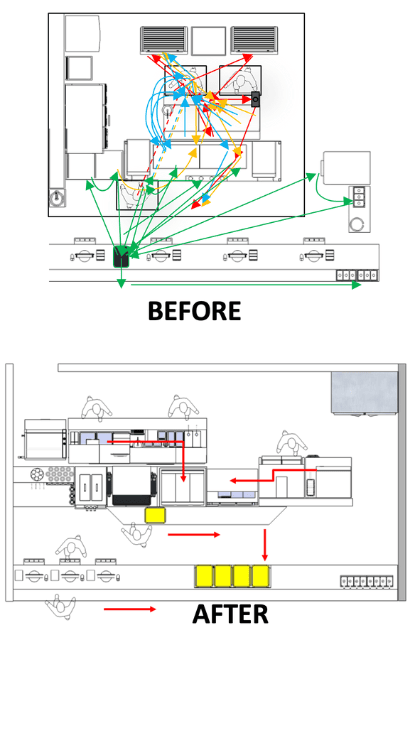

Optimized Kitchen Flow

Problem:

Lack of available restaurant staff in the market and increasing labor costs forces restaurant to review process and procedures.

Process Followed:

Using Restaur-A-tion™ process and video ethnography, fact-based, root cause correlations were identified.

Solution:

Re-designed the kitchen flow and recommended equipment for more effective use of space and reduced labor component. Also reduced the number of non-value-added steps which equaled over 25 minutes per peak hour, saving the client over $3,600 per year in labor, at EVERY location.

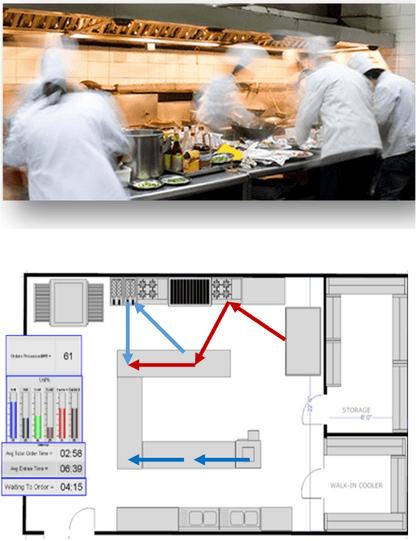

Speed of Service

Problem:

Start-up regional chain was at the critical juncture of expansion through franchising but the business model ROI was constrained by complicated operations, unacceptable speed of service and kitchen size that prevented expansion into an urban market.

Process Followed:

Analyzed peak hour demand and gathered key baseline operating data for current and future menu. Mapped process flows, calculated capacities, brainstormed concepts and quantified costs. Worked with culinary team to brainstorm and develop new processes targeted at reducing labor and prep time.

Solution:

Developed cost-effective modular solution with re-engineered processes utilizing new cooking and holding technologies. Result was reduced service times on average of 4.8 minutes along with improvement in product quality by 4% according to customer surveys.

Bottleneck Identification

Problem:

Process Followed:Even well run, profitable restaurants can benefit from a 2nd set of eyes to make sure that over time and menu expansion and growth that their processes don’t creep and become inefficient.

Solution:Captured key data through observation and video at a “typical” restaurant. Had discussions with crew and customers to help identify focus areas for improvement.

Three critical bottlenecks were found causing an “out of balance” situation. Identified solutions which rebalanced the line and the flow. This provided throughput of 8 more products per peak hour, with an average check of $8, increasing annual sales almost $70,000 per location.

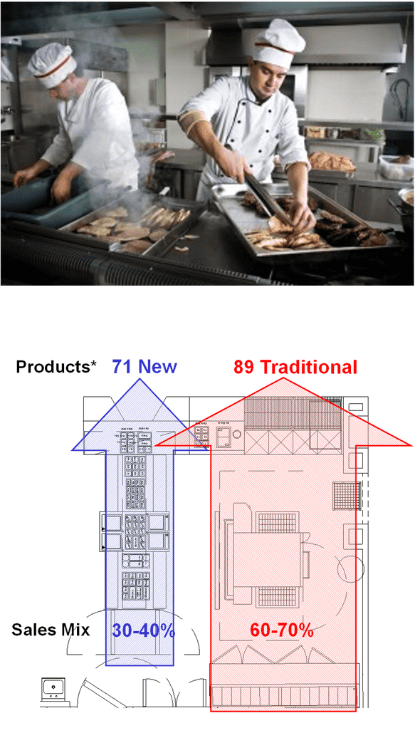

New Daypart Layer

Problem:

Process Followed:Global restaurant chain needed to increase sales. Their dinner business was limited due to security concerns in the city for guests out at night. They concluded that adding a breakfast layer was the best option. The solution had to fit into the existing asset base with minimal cost and operational impact.

Solution:Worked with culinary teams to create a new menu, selected and tested equipment, developed sales forecast and calculated capacities. Then developed station concepts that worked in existing layouts and validated each using a live mock-up simulation to refine and optimize procedures.

Developed cost-effective modular solution with re-engineered processes utilizing new cooking and holding technologies. Result was reduced service times on average of 4.8 minutes along with improvement in product quality by 4% according to customer surveys.